ALLICO Surface Treatment Process

The surface treatment of paper packaging box refers to a series of process technology to beautify, protect and enhance the surface of the box, in order to improve the appearance of the product, enhance the anti-counterfeiting ability and improve the durability of the product. It mainly includes the following treatments: coating, printing, hot stamping,Embossing, UV, laser engraving processing.

The embossing process is a printing process often used for box surface decoration and printing. It produces a raised pattern or text on the surface of the printed matter by applying a hot stamping material (usually metal foil or special ink) to the surface of the printed matter. This process can enhance the texture, appearance and appeal of printed matter.

This is especially popular in the packaging of high-end products, such as luxury goods, gift boxes, high-quality cosmetics boxes, etc. The embossing process can not only enhance the texture and visual appeal of the print, but also establish a unique image for the brand, so it is widely used in the printing and packaging industry.

The debossing process refers to intaglio printing, which is the opposite of the embossing process, by transferring ink or paint to a concave area on the surface of the print to form a concave pattern or text. Debossing process is often used in packaging boxes, which can create a high texture and high-quality appearance.

Especially suitable for luxury goods, high-end cosmetics, wine, chocolate and other high-end products packaging.The debossing process can create a unique, high quality pattern and text on the print, making the product more attractive and added value. It is widely used in the packaging and printing field of high-end brands and products.

Foil stamping is a printing process often used to decorate the surface of a box by transferring metal foil or other special hot stamping material to the surface of the print to create a metallic luster and pattern. This process enhances the texture, visual appeal and luxury of the print. Commonly used effects are gold foil stamping, silver foil stamping ,black foil stamping and so on.

The foil stamping is often used in packaging boxes, especially luxury goods, high-end cosmetics, gift boxes, etc., to highlight the nobility, luxury and uniqueness of the brand.

The UV process is a special coating proce that is often used to decorate and protect the surface of boxes. It rapidly cures UV coatings or inks by irradiating them with ultraviolet light to form a protective layer that is resistant to abrasion, high gloss, scratch, fade and chemical corrosion.The UV process can be used for the surface decoration of the box to increase the high gloss and improve the appearance quality.

The UV process provides an efficient, environmentally friendly, high-quality surface decoration and protection solution that is widely used in a variety of industries to improve product appearance, enhance product quality and increase brand appeal.

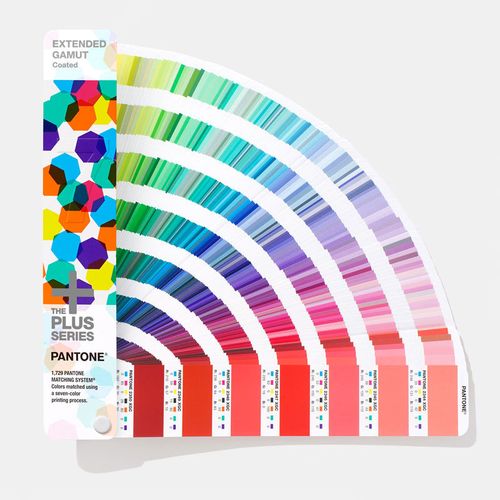

CMYK printing is a color printing process based on the principle of color overlay. It utilizes cyan, magenta, yellow, and black inks to create a full-color image through varying combinations. Cyan, magenta, and yellow are the primary colors, while black is added to enhance depth and contrast. Widely employed in printing books, magazines, brochures, and packaging, CMYK ensures high-quality and realistic color outcomes. It is also utilized as a color mode in digital graphic design, particularly suitable for print output.

In the appearance design of packaging cartons, CMYK four-color printing can be used to create a variety of colors and patterns, including gradient colors, complex patterns, and photographs. These design elements can be accurately rendered on the packaging carton by CMYK four-color printing.

CMYK four-color printing can also be used to produce logos and text on packaging cartons. For example, brand logos, product names, specifications, instructions for use, etc. can be rendered through CMYK four-color printing.

Lamination is a common surface treatment in cartons. Laminating refers to a product processing technology that covers the printing surface with a layer of transparent plastic film to combine paper and plastic. Laminating technology can make the surface of cartons smoother, waterproof, moisture-proof and wear-resistant, and at the same time improve the compressive strength and impact resistance of cartons.

Laminating can be done with different materials and techniques, the most common of which are glossy film and matte film. Bright film, also known as light film, has a crystal clear surface effect with bright and long lasting colors. It has a soft touch and mirror-like visual effect. Matte film, on the other hand, is one of the most widely used in the packaging industry. The best feature is that it does not usurp the role of the owner and can perfectly present the visual elements in the box.