Paper Box Step by Step Manufacturing Process

Our company has 6 production lines and over 100 employees, enabling us to meet the demands of large-scale orders and ensure timely delivery. Our production capacity and human resources allow us to respond quickly to customer needs and maintain a stable product supply.

We have introduced international advanced equipment that utilizes the latest technology and craftsmanship, enabling efficient production of various packaging boxes. These equipment not only ensure consistent product quality but also enhance production efficiency and productivity while reducing costs, providing customers with competitive prices.

We strictly adhere to the ISO9001-2008 quality assurance system, ensuring high product quality and achieving timely delivery through comprehensive quality control and inspection processes.

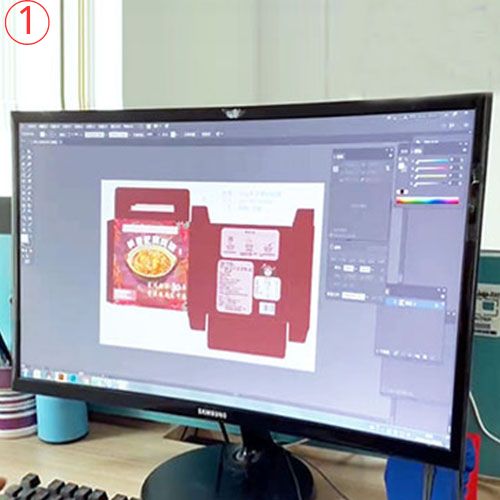

We are familiar with a variety of software, including Adobe Creative Suite, 3D modeling and rendering software, CAD software, color management software, and environmental simulation software to provide professional packaging design services. Our design team is professionally trained to use these software flexibly to ensure high quality and accurate designs.

The process of accurately cutting paper or cardboard according to specifications to achieve the desired size and shape is a crucial production step in a packaging box factory.

According to the design requirements, the corresponding printing plate is produced. Patterns, text and images on the printing plates need to be accurately arranged and typeset according to the design requirements. Use professional graphic design software and print pre-processing software, such as Adobe Illustrator and Adobe Photoshop, to design and prepare the printing plates.

Apply an appropriate amount of glue onto the folded paperboard or paper and assemble the different parts of the box according to the design requirements. Ensure a strong and secure adhesion to prevent loosening or cracking. The process of handcrafting and assembling packaging boxes requires skilled manual techniques and meticulous attention to detail to ensure the production of high-quality boxes that meet design specifications.

The finished packaging boxes undergo an inspection of their appearance to ensure that there are no noticeable defects, damages, stains, or scratches, thereby ensuring that each packaging box meets the quality standards and customer requirements.

The finished packaging boxes are carefully arranged and secured, and then placed into the outer packaging to ensure proper fit and protection between the packaging box and the outer packaging, resulting in a complete product packaging. This process ensures the safety and integrity of the product during transportation and storage.