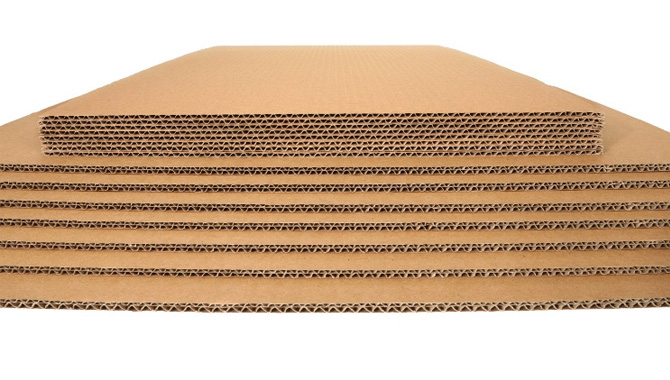

Corrugated Inserts

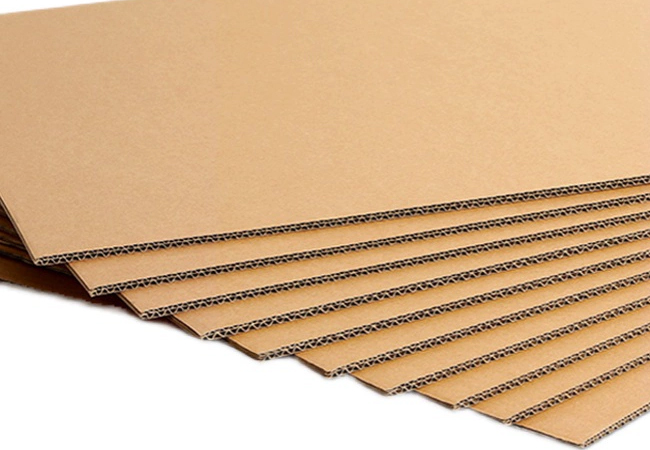

Corrugated inserts sheets are widely used in packaging goods, especially during transportation. They offer effective cushioning and protection, reducing the risk of damage to the goods during transit. Corrugated cardboard sheets can be customized into various shapes and sizes to accommodate goods of different dimensions and shapes.

- Can be easily recycled and reclaimed

- Corrugated core structure, which has excellent cushioning properties

- Corrugated cardboard construction is lightweight but strong

- Different corrugated shapes, board thicknesses, sizes and printing methods can be selected

What ls Corrugated Insert?

Corrugated inserts sheets are crafted from corrugated paperboard, typically consisting of two or three layers of cardboard. They are known for being lightweight, sturdy, and environmentally friendly.

These sheets feature a central layer with a wavy or corrugated core, which is the source of their name. The choice of core material can be tailored to meet specific requirements for strength and durability.

Corrugated inserts Applications

Corrugated liners are widely used in various industries and products:

- Electronics Industry

- Home Goods Indust

- Food and Beverage Industry

- Cosmetic and Personal Care Industry

- Transportation and Logistics Industry

- Pharmaceutical and Health Products Industr

Environmental Friendliness

Corrugated board has excellent environmental friendliness:

- Renewable materials

- Recyclability

- Low-energy manufacturing

- Biodegradability

More Paper Box Inserts And Linings

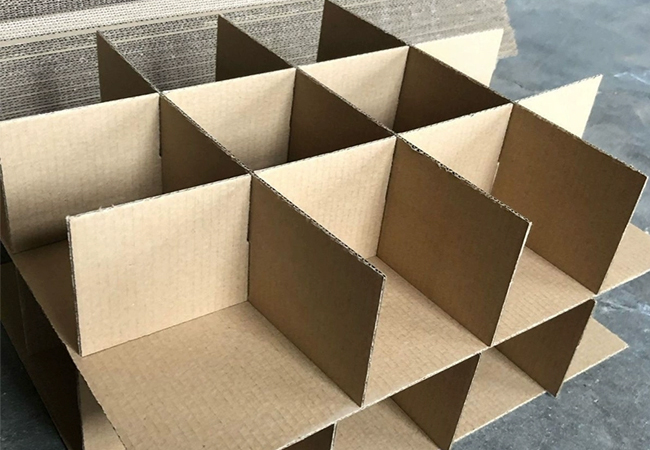

Corrugated paper inserts can be used in packaging and transportation to provide excellent cushioning and protection, ensuring that products remain undamaged during shipping and storage.

Corrugated paper inserts are suitable for various industries and applications, from food packaging to electronic product protection, meeting diverse needs.

Corrugated board is typically more affordable than materials like plastic, metal, or wood, which makes it an economical choice for packaging.Corrugated paper inserts are typically cost-effective, helping businesses reduce packaging costs and improve profitability.

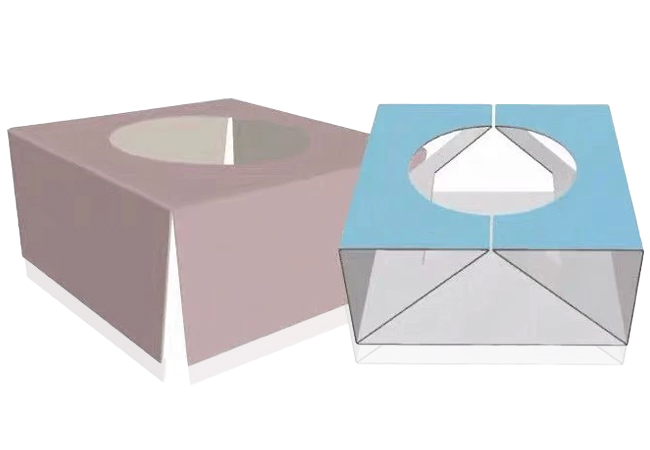

Yes, corrugated board inserts can be customized to fit specific product dimensions andshapes, ensuring a snug fit and optimal protection during shipping.

Carefully place the assembled corrugated board insert into the packaging container. Ensure that the insert matches the internal dimensions of the container to properly accommodate the products.

Corrugated board inserts come in various thickness options, allowing customization basedon the product’s weight, fragility, and level of protection required.

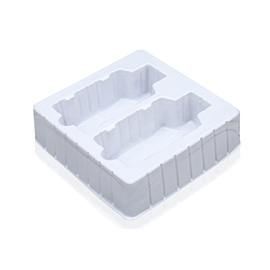

corrugated board inserts can be used in combination with other packaging materials suchas foam, bubble wrap, or plastic trays to provide additional layers of protection.

To ensure optimal product protection with corrugated board inserts, it is essential to selectthe right insert size, design, and material strength, considering the specific needs andcharacteristics of the packaged product.